Climatic chambers

It is of fundamental importance to consider the different environmental conditions to which the product will be subjected In each phase of development and design, both during the production cycle and during the life of the product itself: solar radiation, climatic changes, high humidity rates, etc.

INELTEC climatic chambers allow you to recreate any environmental condition to carry out tests on prototypes, guaranteeing extremely safe, reliable and reproducible results. Produced according to high quality standards and compliant with all CE standards, INELTEC climatic chambers are designed according to the user’s needs: simple and fast to use, long-lasting and customisable according to any request.

- Quick and easy to program;

- PC touch screen positioned in the door;

- Inspection window;

- Ethernet and WiFi communications;

- Remote connection;

- Software with history, alarm management, etc.;

- Gradients from 3º /min ... up to 20º /min.

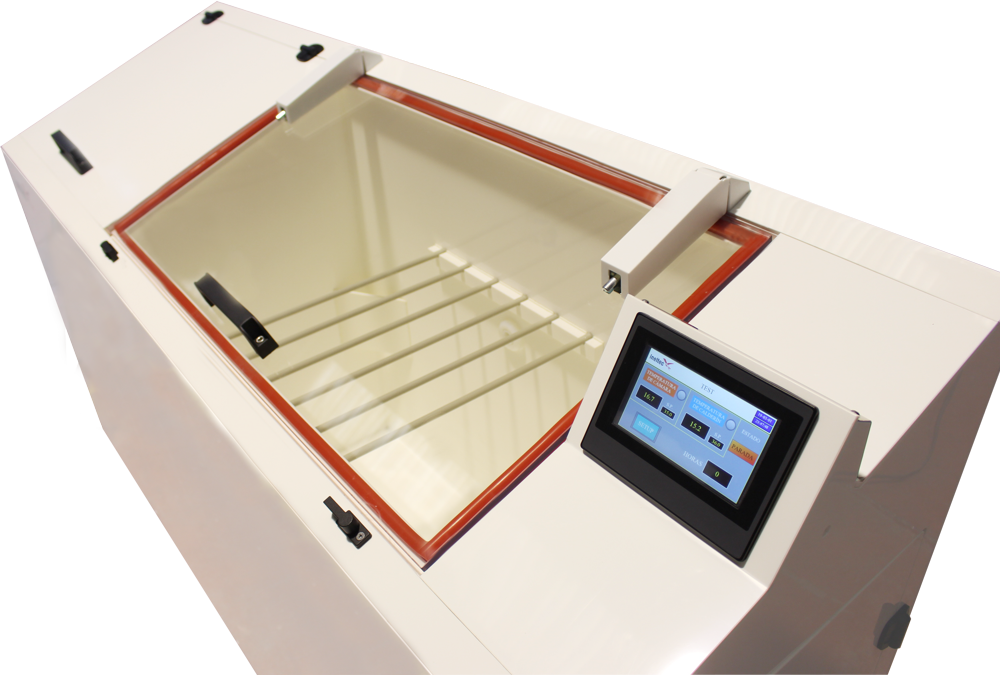

Tabletop climatic and thermal chambers

Even small mundane objects such as medicines, cosmetics and electronic components must meet precise quality standards. The INELTEC tabletop thermal chambers allows the user to carry out temperature tests (cold-hot) on small samples.

- Quick and easy to program;

- Touch screen;

- Observation window;

- 50 mm access hole;

- WiFi / Ethernet / USB communication;

- Remote connection;

- Software: PROCAM-WIN.

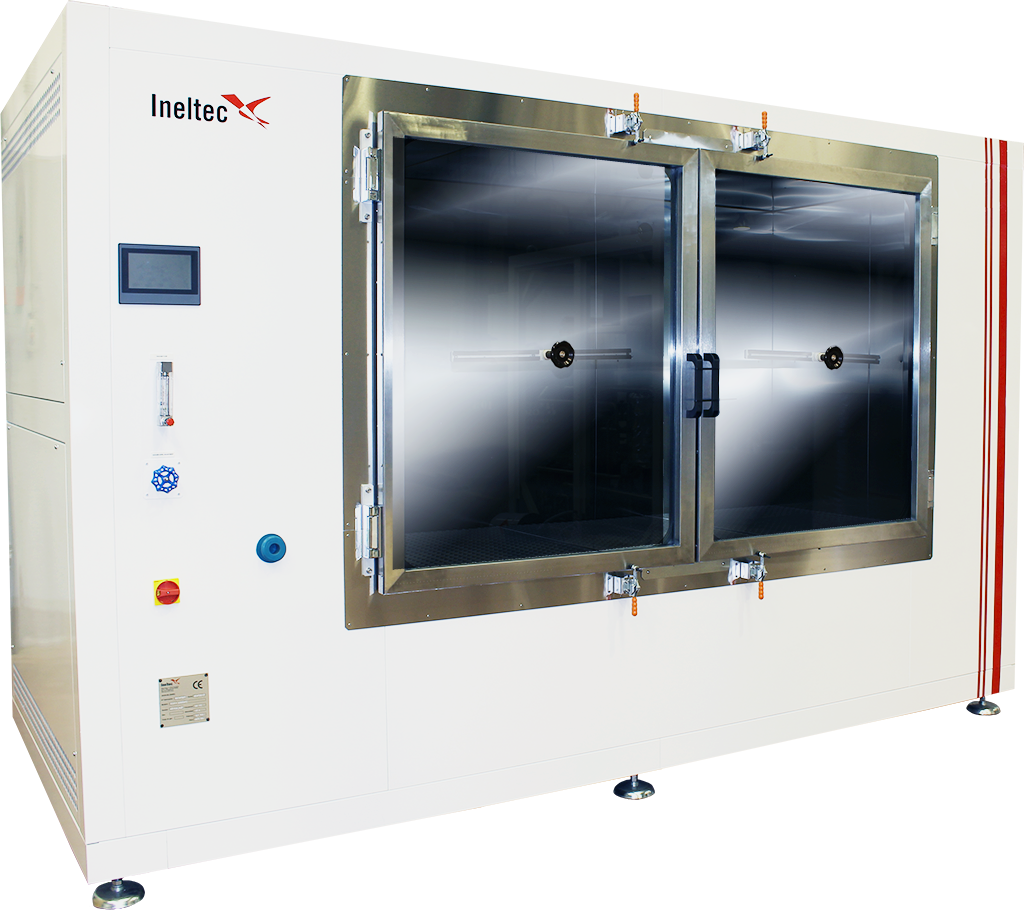

Thermal Shock Chambers

Guaranteeing the resistance, functionality and reliability of a specific product in different environmental conditions is backed up by the results of various tests. It is often essential to check the specimens not only at high or low temperatures but also at sudden and repeated changes in temperature.

Ineltec thermal shock test chambers allow the user to obtain rapid temperature variations in the range between -70°c and 200°c to bring potential defects of components or production processes to light in order to be able to make the necessary product optimisation improvements.

Available in vertical and horizontal versions. Two or three test compartments.

- Quick and easy programming;

- PC touch screen;

- Inspector window;

- Ethernet, WiFi communication;

- Remote connection;

- Software with history, alarm management, etc.;

- Integrated reproduction, certification and time lapse software.

Salt spray chambers

Various products are daily exposed to corrosive effects: high humidity, sea water, antifreeze salt, brackish air. The resistance of materials to corrosion and ageing represents an important safety and quality feature for many products.

Ineltec cyclic corrosion chambers are designed for accelerated corrosion tests, simulating environmental conditions, combining wet-static, salt and climatic phases. Thanks to the solid structure and the highest quality execution, they guarantee perfect temperature regularity and atomisation homogeneity – yielding reliable and precise results.

- Quick and easy to program;

- PC touch screen;

- Ethernet, WiFi communication;

- Remote connection;

- Software with history, alarm management, etc.

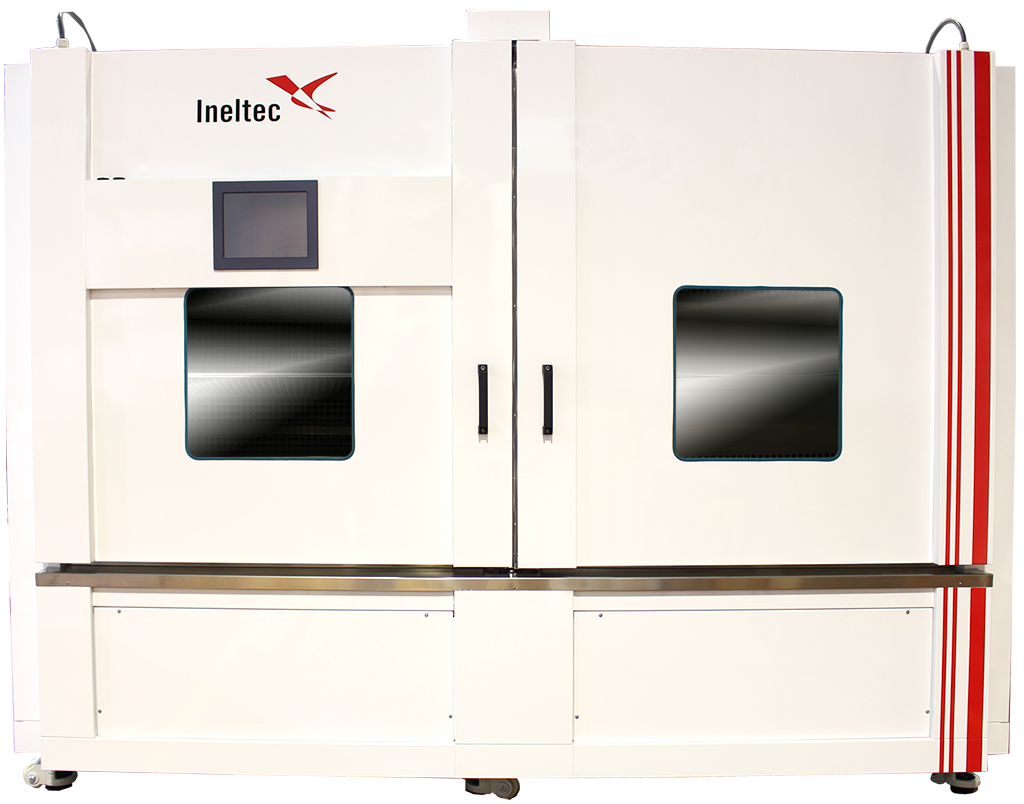

Walk-in and Modular Climatic Chambers

Modular thermal test chambers that one can ‘walk-in’ are designed to facilitate tests on large samples. They are able to accommodate any kind of hot cooling test. These rooms are made with removable panels, so their design and construction is fully adapted to the customer’s needs.

- Quick and easy to program;

- Touch screen PC positioned on the door;

- Observation windows and access holes;

- Fluorescent interior lighting;

- Volumes starting from 3,000 litres;

- Customisable temperature ranges according to requirements;

- Ethernet, WiFi communication;

- Remote connection.

Rain Rooms

The Ineltec rain chamber seal is designed to determine the IP protection degree according to IEC 60529 and DIN 40050-9 standards. The equipment includes an oscillating arch or diffusers for running rain simulations. The simulations are suitable for sealing in electronics, lighting, etc.

- Touch screen;

- Inspector window;

- 50 mm access holes;

- WiFi / Ethernet / USB communication;

- Remote connection.

Dust Chambers

During their life cycle, industrial products are exposed to various atmospheric agents that go well beyond the better-known factors like temperature, corrosion and humidity. In fact, high degradation is often attributable to sand or dust.

Ineltec chambers for dust simulation tests, compliant with the main international standards, allow you to reproduce all the different conditions to test the IP5X and IP6X degree of protection.

Ineltec is able to design bespoke solutions to meet any customer request.

- Touch screen;

- Inspector window;

- 50 mm access holes;

- WiFi / Ethernet / USB communication;

- Remote connection.

High temperature chambers

Today, more and more companies in the most varied sectors need to be able to carry out safe, reliable and precise heat treatments. Ineltec laboratory ovens are designed to perform temperature tests or perform any high temperature maintenance on any product. With variable processing volumes and tolerances up to high temperatures, they guarantee accurate and reproducible results for product development, thermal ageing and quality tests.

Furthermore, Ineltec is able to design bespoke solutions with high volumes where necessary.

- Quick and easy to program;

- Touch screen;

- Standard or customised models;

- Several options and accessories available.